Acoustic Insulation

HIGH-PERFORMANCE ACOUSTIC INSULATION

For over a decade the name BARRIER has been associated with the highest

performance and most technologically advanced thermal insulation in the

world. Now BARRIER Ultra-dBtm offers the same quantum leap in noise control

technology. BARRIER Ultra-dB acoustic insulation is a carefully engineered

soundproofing material intended for those applications requiring superior

performance without the size and weight of laminated foam and lead/vinyl

products.

With BARRIER Ultra-dB acoustic insulation you get:

Superior noise reduction

with 48% less weight

Superior noise reduction with 25% less thickness

The widest frequency control of any flexible sound insulation product

The highest quality polyether foam - 4x the life of polyurethane

A uniquely engineered, six-layer noise control solution

A wide frequency band solution -

Sound is an incredibly complex thing. Varying frequencies, amplitude,

intensity, harmonics, pressure level, dB(a), dB(b), dB(c), dB(m), dB(v),

dB(spl), sone scale, phon scale and on it goes. For the tortured ear it

all adds up to just one thing - NOISE. Those of us trying desperately

to get some peace and quiet may find it hard to believe that there isn't

some magic material capable of just blocking it all off. Unfortunately,

no such material exists.

While many materials

block sound - no single material blocks noise. The problem is the frequency

range. What we call "noise" nearly always consists of many different

frequencies. The sound spectrum analysis on the right (click for larger

image) shows a 3-cylinder diesel engine running at 2,800 rpms. The "noise"

it emits includes frequencies ranging from 22Hz to over 11kHz. No single

material can effectively block all these frequencies. The only way to

attenuate this kind of noise is to select a combination of materials which

work together to effectively control sound across a broad spectrum. In

practice this is harder than it may seem since different materials grouped

together change resonance characteristics and can respond in unexpected

ways.

When it comes to effective noise attenuation, it is the quality of the

materials selected and the way in which they are combined that determines

the performance of the finished product. As with all Glacier Bay products,

superior engineering is the secret to the superior performance of Ultra-dB.

The physics of multilayer acoustic insulation materials.

Noise is energy and, as you know, you can't just get rid of energy. What

you can do is change its form. That's what acoustic (sound) insulation

does. It changes the energy contained in sound waves into heat. The more

effectively it does this the greater the sound reduction. To understand

why BARRIER Ultra-dB works so much better than our competitors, lets first

take a look at the basics of multilayer sound-control technology.

Multilayer "foam-vinyl-foam" type laminates are an attempt by manufacturers to try to attenuate a wider range of frequencies than would be possible with one material alone. The individual layers are often described by their functionality as the "absorption-damping-decoupling" layers. The "absorption" layer (nearest the noise source) is comprised of foam which is of a density that allows it to be moved (i.e. vibrated) by higher frequency sound waves. Energy is required to move the foam and this energy comes from the sound waves themselves. The frequency of sound which most effectively moves the foam the that particular material's "resonant" frequency. Consequently, it is the resonant frequency which is the one best attenuated by the material. Because they are located nearest the noise source, absorption layers also help to inhibit the formation of standing waves.

The resonant frequency of foam is quite high - above 250 - 500 Hz depending on thickness. Frequencies lower than that pass through virtually unaffected. Attenuating these lower frequencies is much more difficult and is the primary function of the "damping" layer. The damping layer used in conventional sound materials is very heavy (lead or a filled vinyl of similar density) and relies on high mass to provide a lower resonant frequency and harness the energy contained in these waves. The waves hit the damping layer and, as with the lighter foam, make it vibrate. Unfortunately, because of the weight of the damping layer, this vibration can create a new problem. If the vibrating mass is allowed to mechanically transfer energy to another surface (such as a wall or bulkhead) the noise is simply transferred through and radiated off the other surface. It is the job of the "decoupling" layer to prevent this from happening.

The BARRIER Ultra-dBtm

difference.

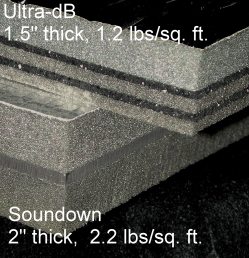

Conventional acoustic insulation materials work well if you use sufficient

weight and thickness. There are many manufacturers and little difference

between product performance other than the differences in the thickness

and weight. The design goal of BARRIER Ultra-dB was to provide greater

noise reduction in a thinner, lighter material.

To accomplish this

is it was necessary to find a way to better attenuate low frequencies

without resorting to the high mass of conventional damping layers. What

was needed was a lightweight material which would resonate at low frequencies

and effectively dissipate that energy internally with a minimum of linear

movement.

To accomplish this is was necessary to get away from the type of uniform,

molded "sheet" products (filled vinyl or lead) which is commonly

used. The uniform nature of these materials limits their frequency range

and requires that the entire sheet be moved as a whole to dissipate energy.

This movement, as previously mentioned, introduces its own set of isolation

problems.

BARRIER Ultra-dB

solves the damping layer problem in a particularly ingenious way. Rather

than using a uniformly molded sheet, our damping layer is a composite

made up of randomly adhered elastomeric particles of varying sizes, shapes,

weights, densities and durometers. When sound waves strike, different

particles within the layer will resonate depending on the frequency of

the wave. At any given frequency only a fraction of the particles vibrate.

Each vibrating particle is loosely suspended between other particles,

most of which do not resonate at the same frequency. This permits the

energy contained within the vibrating particle to be dissipated into the

adjacent material rather than through movement of the entire layer.

|

|

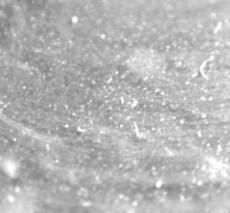

| Macro photograph of a typical "filled vinyl" damping layer shows its uniform structure. | Image of the BARRIER Ultra dB damping layer reveals its granular, non-uniform composition. |

The result is better attenuation over a wider frequency range and with

the problems associated with a single, heavy vibrating mass.